Water Mitigation Equipment

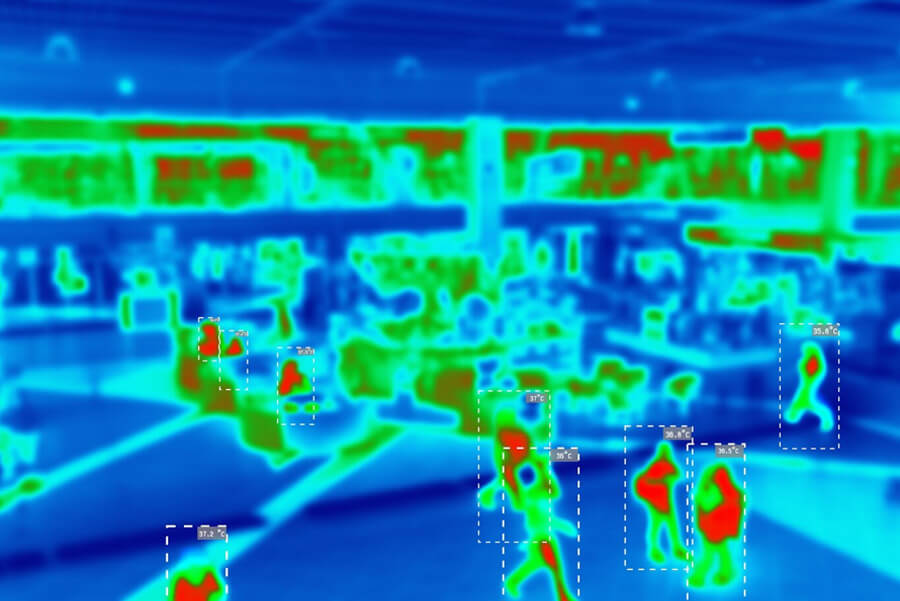

Thermal Imaging

Thermal imaging cameras are advanced diagnostic tools utilized in water mitigation and restoration to detect temperature variations within building materials. By identifying subtle changes in surface temperatures, these devices enable restoration professionals to locate hidden moisture without the need for invasive methods, such as drilling or cutting into walls, ceilings, or floors. This non-destructive approach preserves the structural integrity of the property while providing precise and reliable data for assessing water damage.

Identifying Hidden Moisture with Infrared Technology

Using infrared technology, thermal imaging cameras capture detailed heat signatures, allowing technicians to pinpoint areas where moisture may be trapped. Wet materials retain heat differently than dry materials, and this contrast is displayed as a thermal gradient on the camera's screen. This capability is especially valuable in identifying moisture that may not be visible to the naked eye, such as water concealed behind drywall, under flooring, or within insulation.

Assessing Water Damage with Thermal Imaging

We know how important it is to get back to normal as quickly as possible. By partnering with PCC Cleaning & Restoration, you benefit from having a knowledgeable team that bridges the gap between you and your insurance carrier. Our experience with insurance claims for water, fire, mold, storm damage, and reconstruction projects allows us to anticipate challenges, resolve issues efficiently, and ensure your restoration proceeds smoothly.

The Role of Thermal Imaging in Water Mitigation

Thermal imaging cameras are indispensable for their efficiency, accuracy, and versatility. Their ability to streamline inspections and provide actionable insights makes them a critical component in modern water mitigation practices, enhancing both the quality and speed of restoration efforts while minimizing disruption to the property owner.

Moisture Meters

Moisture meters are precision instruments designed to measure the moisture content in building materials such as wood, drywall, concrete, and other structural components. These devices are an essential tool in water mitigation and restoration, enabling professionals to accurately assess the extent of water intrusion and develop an effective drying strategy. By providing real-time, quantifiable data, moisture meters help identify areas affected by moisture, even those that may not show visible signs of water damage.

Comparing Pin-Type and Pin-Less Moisture Meters

There are two primary types of moisture meters: pin-type and pin-less. Pin-type meters measure moisture by inserting probes into the material, offering highly accurate readings of the internal moisture content. Pin-less meters, on the other hand, use non-invasive technology to detect moisture near the surface, making them ideal for fragile or finished materials that could be damaged by penetration. Advanced models may also combine both technologies, providing versatile solutions for a wide range of applications.

The Role of Thermal Imaging in Water Mitigation

Thermal imaging cameras are indispensable for their efficiency, accuracy, and versatility. Their ability to streamline inspections and provide actionable insights makes them a critical component in modern water mitigation practices, enhancing both the quality and speed of restoration efforts while minimizing disruption to the property owner.

Monitoring Moisture Levels Throughout the Drying Process

Moisture meters play a critical role throughout the drying process, from the initial assessment to ongoing monitoring and final verification. During the assessment phase, these devices help identify the scope of the damage and pinpoint moisture-laden areas that require focused drying efforts. As drying progresses, technicians use moisture meters to monitor changes in moisture levels, ensuring that equipment such as dehumidifiers and air movers are performing effectively. Finally, moisture meters are used to confirm that materials have been returned to their pre-loss moisture levels, ensuring the property is safe for reconstruction and occupancy.

The Importance of Moisture Meters in Water Mitigation

The ability to provide precise, reliable, and consistent moisture readings makes these tools invaluable in preventing secondary issues, such as mold growth, warping, or structural instability. Moisture meters are a cornerstone of professional water mitigation practices, delivering the data needed to make informed decisions and achieve successful restoration outcomes.

Hygrometers

Hygrometers are sophisticated instruments designed to measure and monitor the relative humidity (RH) levels in the air, providing critical data for maintaining optimal environmental conditions during water mitigation and restoration projects. By accurately gauging the moisture content in the air, hygrometers enable technicians to assess the drying environment and make necessary adjustments to ensure the efficiency and effectiveness of the drying process.

In water mitigation projects, hygrometers are utilized at multiple stages. During the initial assessment, they help establish baseline humidity levels and identify areas requiring intervention. Throughout the drying process, they enable continuous monitoring to ensure that humidity levels remain within target ranges. Finally, hygrometers are used to confirm that the environment has been adequately stabilized before restoration or reconstruction begins.

Utilizing Hygrometers Throughout the Drying Process

Maintaining appropriate humidity levels is essential for preventing secondary damage to materials, such as warping, swelling, or microbial growth, which can occur when moisture levels remain uncontrolled. Hygrometers serve as a vital tool in creating a balanced drying environment by working in conjunction with dehumidifiers, air movers, and other drying equipment.

Preventing Secondary Damage with Humidity Control

Advanced hygrometers often feature digital displays, data logging capabilities, and integrated sensors for monitoring temperature and dew point in addition to humidity. This combination of measurements provides a comprehensive understanding of the drying environment, allowing technicians to fine-tune their equipment settings to achieve the desired outcomes.

Features of Advanced Hygrometers

The precision, versatility, and reliability of hygrometers make them indispensable for achieving professional-grade results in water damage restoration. Their role in monitoring and controlling the drying environment contributes to faster recovery times, reduced risk of complications, and the successful restoration of affected properties to pre-loss conditions.

The Role of Hygrometers in Professional Water Mitigation

Advanced hygrometers often feature digital displays, data logging capabilities, and integrated sensors for monitoring temperature and dew point in addition to humidity. This combination of measurements provides a comprehensive understanding of the drying environment, allowing technicians to fine-tune their equipment settings to achieve the desired outcomes.

Features of Advanced Hygrometers

Air Movers

Air movers are specialized devices designed to enhance airflow across surfaces, including walls, floors, ceilings, and other affected areas, during water mitigation and restoration projects. By significantly increasing air circulation, these units expedite the evaporation process, which is critical for effective and efficient drying of wet materials.

Targeted Airflow for Effective Drying

The design of air movers focuses on maximizing airflow directionality and intensity, allowing technicians to target specific areas or distribute air uniformly throughout a space. This targeted approach ensures that moisture trapped within porous materials, such as drywall or carpets, is rapidly evaporated, minimizing the risk of secondary damage, such as warping, swelling, or microbial growth.

Features of Modern Air Movers

Modern air movers often feature adjustable fan speeds, stackable designs for multi-directional airflow, and lightweight construction for easy transport and deployment. They are engineered to complement other drying equipment, such as dehumidifiers, by maintaining optimal conditions for moisture removal. When strategically positioned, air movers create a controlled drying environment that accelerates project timelines while preserving the structural integrity of the affected building materials.

The Importance of Air Movers in Water Damage Restoration

In water damage restoration, air movers are indispensable for ensuring a thorough and reliable drying process, making them a cornerstone of professional mitigation efforts. Their ability to work efficiently in conjunction with other tools underscores their importance in restoring spaces to pre-loss conditions.

Dehumidifiers

Dehumidifiers are essential for reducing moisture levels in the air during water mitigation projects, ensuring efficient and thorough drying of affected areas. These advanced machines utilize cutting-edge desiccant or refrigerant technology to extract water vapor from the surrounding environment, effectively controlling humidity levels. By removing excess moisture, industrial dehumidifiers help mitigate the risk of secondary damage, such as mold growth, mildew, and the deterioration of building materials like wood, drywall, and insulation.

Comparing Desiccant and Refrigerant Dehumidifiers

Desiccant dehumidifiers are particularly effective in low-temperature environments or when an exceptionally low relative humidity is required, as they rely on a moisture-absorbing material to capture water vapor. Refrigerant dehumidifiers, on the other hand, condense moisture by cooling air to its dew point, making them highly efficient in warmer conditions. Both types of dehumidifiers play a critical role in creating a stable and controlled environment conducive to rapid drying, preserving the integrity of the structure, and preventing long-term complications.

High-Capacity Performance for Large-Scale Projects

Dehumidifiers are engineered for high-capacity performance, making them indispensable for large-scale water mitigation projects in commercial and residential settings. Their robust construction and adjustable settings ensure adaptability to various scenarios, providing reliable and consistent results throughout the drying process.

Air Scrubbers

Air scrubbers are advanced filtration systems designed to improve indoor air quality by capturing and removing airborne contaminants during water mitigation and restoration projects. These devices play a crucial role in creating a clean, safe, and controlled environment, particularly in spaces affected by water damage, where the risk of mold growth, bacterial proliferation, and particulate dispersion is elevated.

HEPA Filtration for Air Purification

Equipped with high-efficiency particulate air (HEPA) filters, air scrubbers are capable of trapping up to 99.97% of particles as small as 0.3 microns. This includes mold spores, dust, pollen, bacteria, and other microscopic contaminants that can compromise indoor air quality and pose health risks to occupants and workers. Many air scrubbers also feature multi-stage filtration systems, incorporating pre-filters and activated carbon filters to address larger debris and odors caused by moisture or microbial growth.

Strategic Placement of Air Scrubbers

During the water mitigation process, air scrubbers are strategically placed to create a negative air environment or provide recirculating filtration, depending on the project requirements. By continuously cycling and purifying the air, these devices help reduce the spread of contaminants and ensure compliance with industry standards for air quality.

Air Scrubbers in Sensitive Environments

The use of air scrubbers is particularly critical in sensitive environments such as hospitals, schools, or commercial spaces, where maintaining a safe and hygienic atmosphere is paramount. Their robust construction, portability, and versatility make them an indispensable tool in the restoration industry, enhancing both the efficiency and safety of the mitigation process while protecting the health of all individuals involved.

Desiccant Dehumidifiers

Desiccant dehumidifiers are highly specialized drying systems that utilize advanced moisture-absorbing materials, such as silica gel or similar desiccants, to effectively extract water vapor from the air. Unlike refrigerant-based dehumidifiers, which rely on condensation to remove moisture, desiccant units operate by passing air over a moisture-absorbing desiccant material, which binds with the water molecules and removes them from the environment. This process allows desiccant dehumidifiers to perform exceptionally well in low-temperature environments or situations where achieving extremely low relative humidity levels is critical.

Ideal Applications for Desiccant Dehumidifiers

Due to their unique moisture removal technology, desiccant dehumidifiers are ideal for applications that demand precise humidity control, such as drying structural materials in cold climates, preventing corrosion in industrial settings, or mitigating water damage in sensitive areas like basements, crawl spaces, and storage facilities. These units excel in environments where traditional refrigerant dehumidifiers may be less effective, particularly when ambient temperatures fall below 50°F, as their performance is not limited by air temperature or dew point conditions.

Achieving Extremely Low Humidity with Desiccant Dehumidifiers

Desiccant dehumidifiers are also valued for their ability to produce extremely dry air, with some systems capable of achieving relative humidity levels as low as 10-15%. This makes them particularly effective for drying dense or difficult-to-access materials such as hardwood floors, plaster, concrete, and structural cavities where excess moisture can remain trapped.

Reliability and Performance in Large-Scale Projects

Built for reliability and high-capacity performance, desiccant dehumidifiers are often utilized in large-scale water mitigation projects, commercial applications, and specialty drying scenarios where conventional equipment may fall short. Their robust construction, versatility, and ability to maintain consistent drying conditions make them an essential tool for restoration professionals striving to achieve thorough, efficient, and dependable moisture control.

Extractors

Water extractors are essential tools in water mitigation and restoration, specifically designed to remove standing water from affected areas with speed and efficiency. By eliminating excess water quickly, these machines help minimize property damage, reduce the risk of mold growth, and set the stage for effective drying and restoration processes.

Truck-Mounted vs. Portable Water Extractors

Water extractors are broadly categorized into truck-mounted units and portable units, each serving specific needs and scenarios. Truck-mounted extractors are powerful, high-capacity systems permanently installed in service vehicles. They are particularly suited for large-scale water removal tasks, such as commercial buildings, multi-unit residential properties, or flood-damaged areas requiring rapid, heavy-duty water extraction. These units provide superior suction power and are capable of handling extensive water volumes, making them indispensable for large restoration projects.

Advantages of Portable Extractors

Portable extractors, on the other hand, offer mobility and flexibility, making them ideal for smaller-scale jobs or locations that are difficult to access, such as basements, tight crawl spaces, or upper floors of buildings. Despite their compact size, modern portable extractors are equipped with advanced features, including adjustable suction power, heated water recovery options, and lightweight designs, ensuring they deliver professional-grade performance in a variety of settings.

Integrating Water Extractors with Other Mitigation Equipment

Both types of extractors are engineered to work seamlessly with other mitigation equipment, such as dehumidifiers and air movers, to provide comprehensive water damage restoration solutions. Their ability to remove water from carpeting, upholstery, flooring, and other surfaces not only expedites the drying process but also reduces the risk of secondary damage, such as delamination, swelling, or structural weakening.

Enhancing Project Efficiency with Water Extractors

In addition to their technical capabilities, water extractors contribute significantly to project efficiency by allowing technicians to prioritize drying and restoration efforts. By rapidly addressing water accumulation, they help contain the damage, protect building materials, and improve overall project timelines. These tools are a cornerstone of professional restoration practices, ensuring properties are restored to safe, dry, and habitable conditions.